Having your ignition timing set correctly could mean the difference between having good day and a very, very bad day. Incorrect ignition timing can lead to poor fuel economy, low power or even a blown motor. Too little timing and you lose performance, too much timing and you start breaking things (and the obvious loss of performance that comes with that). Having too much advance in your timing is much worse than having too little. Too much can lead to pinging or detonation which is extremely harmful to your motor.

This can lead to melted pistons, cracked pistons, breaking piston rings or even catastrophic engine failure. It’s always in one’s best interest to be cautious when adjusting timing and to go in small increments.

The best thing to do when wondering what to set your timing is to be conservative and stick to the factory settings. If you do plan on adding more timing (IE more advance), then start small and go for a test drive. Listen for any signs of pinging, it tends to sound like marbles rattling around in a tin can. If you hear anything that sounds remotely close to pinging, do not attempt to go to wide open throttle or beat on the car. Stop, whip out your timing light, take some timing out and go for a test drive.

Let’s start with some general identification:

1: This red clamp is an inductive pick-up that gets clipped onto the number 1 cylinder spark plug wire. It picks up the spark signal through the wire.

2. The red clamp goes onto the positive end of your car battery and the black clamp goes onto the negative end. This will provide power to the timing light.

3. The gun (Duh).

It’s a very simple tool, now let’s move to the timing gun itself and some of its features:

1: When pressed and held, this trigger will activate the gun and begin emitting the strobe light. (Some guns actually have a button instead of a trigger)

2. The strobe light will be emitted from this end of the gun.

3. This particular timing gun has what’s called a “dial back”, mainly meant for harmonic balancers that do not have multiple timing marks or that only have top dead center marked on them. We’ll leave it on the “zero” for now.

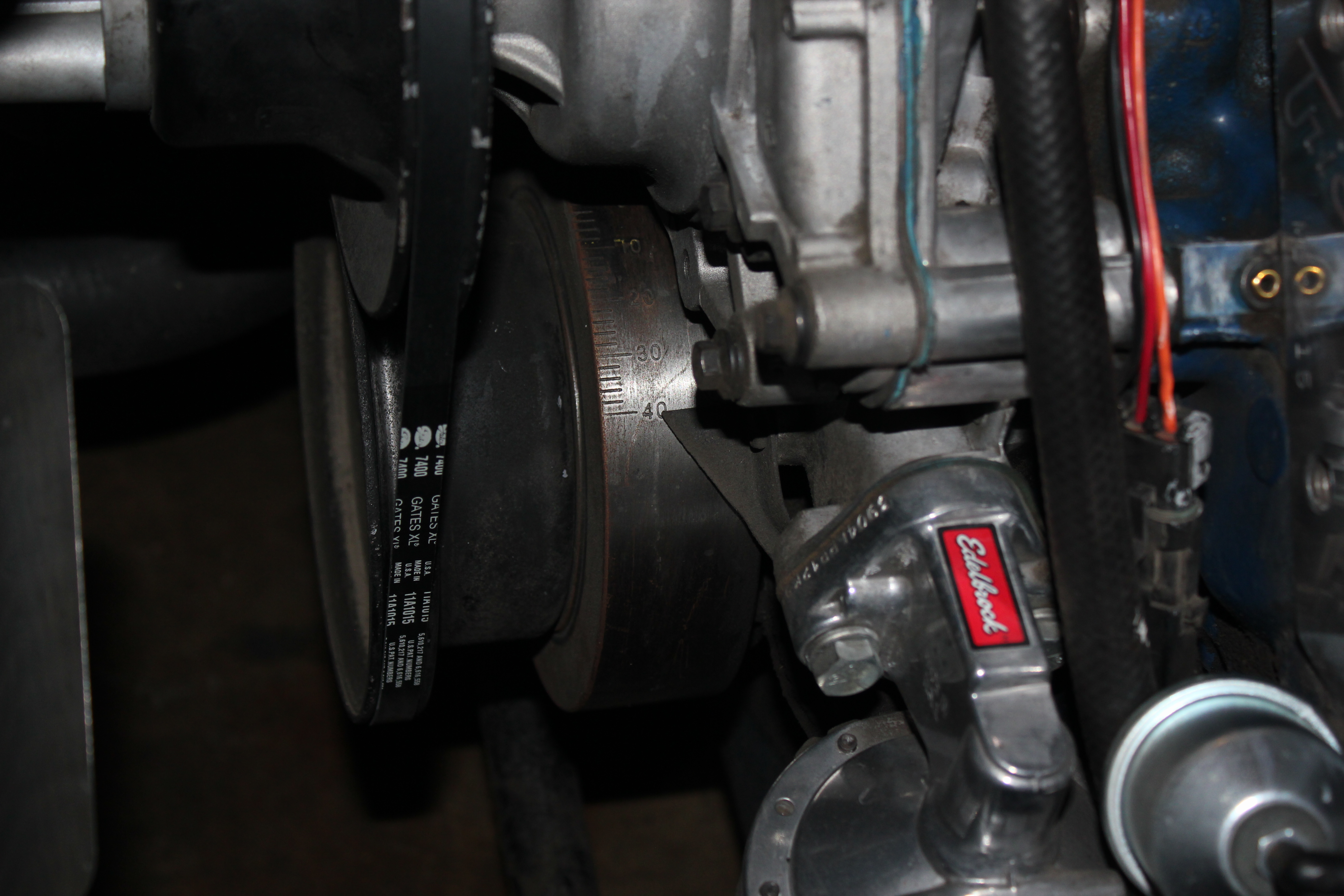

We’ll now look at the harmonic balancer. Notice how there are a series of numbers stamped onto it, they range from 0-40; these represent the amount of timing in degrees. There is also a timing pointer currently pointing at the 40 mark on the balancer. The zero indicates top dead center on the number 1 piston, the numbers below it are how many degrees before top dead center the number 1 piston is.

To start checking ignition timing, unplug the vacuum advance and plug the port off on your carburetor. The vacuum advance will skew your timing readings when trying to set a baseline. From here you can identify the number 1 piston and its corresponding spark plug wire. You will need to clip the pick-up from the timing light to this wire. Try to isolate the spark plug wire from the adjacent wires to avoid mixing signals. In the case of our Ford 302, the number 1 cylinder would be the front passenger side piston.

Next, locate the distributor hold down clamp and loosen it just enough so that you can rotate the distributor. Do not loosen this clamp too much or else your distributor will be turning by itself as the motor is running. Rotating the distributor clockwise or counter clockwise is how you adjust the amount of timing! Do not rotate the distributor too much as even the slightest turn will change the timing. In our case, rotating the distributor clockwise will advance the timing (Give it more timing) and rotating it counter clockwise will retard the timing (Take out timing).

Clamp the red and black leads onto your battery and route all the wires away from spinning objects and your exhaust, get in the car and start it. Avoid doing this in direct sunlight as it will be almost impossible to see the strobe light against the harmonic balancer. If you have a dial back timing gun, make sure that the dial is set to zero. Point the timing gun at the timing pointer above the harmonic balancer and press the trigger, the strobe will begin flashing and illuminating the corresponding degree number. The timing pointer will line up with a corresponding number on the harmonic balancer; that is your initial timing setting. Rotating the distributor will change that number, take note of where your timing is currently set.

For now we will leave the initial timing (your timing at idle) at 10 degrees. Have a helper get in the car and throttle up the motor while you have the timing gun pointed at the timing marks; take note at the highest reading. In our case, the timing would reach 31 degrees at 3000 RPM and would not go any higher. This is the total timing. As engine RPM increases, weights inside the distributor spread out through centrifugal force and add more timing. This is called a mechanical advance. In our case, the mechanical advance added another 21 degrees on top of our initial 10 degrees of timing for a total of 31 degrees.

Initial timing is not as important as total timing (10 from our initial+21 from our mechanical advance). Having too much total timing is what will cause damage. From here we shut the car off, tightened the distributor hold down clamp, removed the timing light and plugged our vacuum advance in. After some more timing changes, we found that the car runs best with 34 degrees of total timing, meaning 13 degrees of initial plus the 21 degrees that is added from the mechanical advance. We found it to give good power with no signs of pinging or detonation.

Depending on the distributor you have, one can change how much extra timing the mechanical advance adds. This is done by changing a stop bushing in the distributor to either limit or add more travel to the mechanical advance. Most aftermarket distributors will come with an assortment of springs, bushings and a reference chart to adjust what RPM the timing maxes out at or how much mechanical advance is given.